T4 Syncro – which kind of gear oil?

We are not experts for gear boxes, but we are frequently asked which gear oil we recommend for the T4 Syncro. In the following we would like to share the outcome of our research:

We are not experts for gear boxes, but we are frequently asked which gear oil we recommend for the T4 Syncro. In the following we would like to share the outcome of our research:

The deposit for an intact viscous coupling of the T4 Syncro is € 350.

Meanwhile it’s common, that the splines of the VC housing are a weak point and often worn out. Effects of worn splines are not serious in the first place (except for some tictac noises), but at some point the gearing is totally sheared off and the 4WD becomes a 2WD.

Practically we haven’t seen such an example yet, but we will probably see such damage in the next years.

It was suspected that high-torque TDI engines are responsible for fast wear of splines. Until recently, we only visually examined the splines and “felt” the backlash by hand – not a satisfying situation. That’s why we developed a special measuring tool, which measures the backlash in degree of arc. Now we got reliable data for the first time:

|

|

Results:

From our tested sample of 67 VC’s have got 7 a backlash greater than 1° – what we see as the upper wear limit. The minimum value is around 0,4° btw.

The 7 worn VCs got not special similarities:

The only similarity that can be seen, is that these 7 Viscos were heavily used. Our guess is that housing splines primarily suffer from tension on asphalt due to extremely hardened VC’s.

To see that over 10% of old VCs have these worn splines, was even to us astonishing. Good VCs are becoming quite rare unfortunately.

You may wonder why we started to offer a special VC-setup for stronger engines (TDI, Subaru…). What looks like a sophisticated marketing strategy was actually born out of necessity:

We started to rebuilt VCs with original Steyr-Puch setup, and testdrivers used to be happy with it. Also we had superior experiences in tough offroad situations (sand, mud..) with our own AAZ-Syncro.

A German Syncro driver went on a Sahara expedition in Summer 2017 with our VC and was rather unhappy. He sent us videos which showed the rear axle digging in sand, while the front axle was standing still. After 30sec the front axle kicked in, but it was much too late.

So he claimed that our VC isn’t working well, and we thought that maybe something is wrong with our VC. After his expedition he sent us the VC back to Austria and we put it on the teststand. Surprise, surprise the VC was working perfectly – and showed practically the identical test chart as before.

After that we asked the German Syncro driver about his engine, and he told us that he is driving a special TDI-Conversion (AFN mTDI) with around 280 to 290Nm and big 16′ wheels. That’s the point when we looked into our documents and started some calculations…

The Steyr-Puch VC was once designed for the 1,6 TD JX with 138Nm. The stronger 2,1 WBX has around 170Nm – but at higher RPM (2800 instead 2500). So the worst thing (worse in case of transferring power) for the VC is high torque at low RPM – but that’s exactly what a TDI does (RPM 2000).

Originally the torque from the 1,6 TD JX engine goes 60% to the rear and 40% to the front (measured by W.Peschke in his dissertation). All additional torque will just increase the torque on the rear axle – especially when it comes at low RPM.

So we did some calculation and made another VC setup for the German Syncro driver with 70% more torque (210Nm@75RPM). Customer is now happy and did some tests in sand.

A few months later, Tanja followed Facebook’s call for help from globetrotters “Resfeber”. Their VC showed little effect in the Mongolian sand and the faced several times the risk to get stuck.

The community agreed that their VC is probably “failed open”. We opposed this and assumed that their strong TDI engine causes an inappropriate distribution of driving forces. At the same time we offered our help and sent them a specially adjusted TDI-VC. After we got their old VC to Austria, it turned out that it is even at the upper end of the standard Steyr-Puch tolerance.

The short video clips shows clearly the difference:

We are driving currently the same setup in our own Syncro to get an idea about the increased binding in turns on tarmac. At the original Steyr-Puch VC setup (for JX engine) the minimum torque is around 120 Nm. For a 1Z TDI, we recommend increasing VC’s torque to approx. 180 Nm (+ 50%). We think that’s the upper limitation for driving without a decoupler in urban traffic. But that’s just our personal opinion – someone can see it differently.

But one’s for sure: Since then, we always ask customers about their specific vehicle data (engine / tires / area of application) to give them individual advice about the ideal VC setup.

Since the sources for old T3 VCs are slowly drying up, we are forced to raise the deposit price for the T3 VC to € 250 by January, 1st 2020 for the first time.

As recently requests for overhauling the T4 viscous coupling are piling up, we want to give you a short overview, what we are currently working on and what the main challenges are.

As we mentioned in the last section of this blog article already, a working viscous coupling will always relieve the gear box from a certain amount of load – even on dry pavement.

Unfortunately, we were not able to quantify this percentage. Now, for the first time, we have reliable measurements for quantifications, which is quite amazing.

Inquiries like this are quite common, since the intended functioning of a viscous coupling often could not be experienced. (more…)

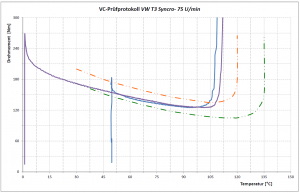

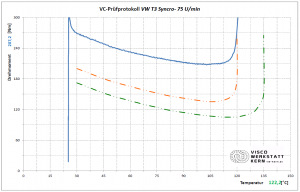

We are frequently asked which gear oil we recommend for the T3 Syncro. The official VW guideline from the ‘80s speaks of 75W90-GL4 for differential & transmission.

But our recommendation is different:

For the highly stressed hypoid teeth, in which the crown and pinion touch only along a small surface area (extreme surface pressure), the GL5 standard is the optimum. For this purpose, the base oil is provided with numerous additives.

Although the same hypoid gear pattern is also present in the manual transmission, consideration must be given here to the synchronizer rings of the gear wheels. Because GL5 lubricates so well, it can cause the synchronizer rings in the transmission to slip and partly lose their function – which can cause gears grinding and wear to occur when changing gear.

In addition, the additives of the GL5 oils can attack the non-ferrous metal component (Molybdenum coating) of the synchronizer rings.

But there are also oils with the unofficial name GL4 / GL5 (GL4 +), which manage the balancing act between the hypoid gearing’s ideal lubrication and a residual friction for synchronization.

Gearbox oils are classified by the American Petroleum Institute (API) using GL ratings. The higher an oil’s GL-rating, the more pressure can be sustained without any metal-to-metal contact taking place between transmission components.

GL-4:

Designates the type of service characteristic of spiral-bevel and hypoid gears in automotive axles operated under moderate speeds and loads. Gear oils to API GL-4 are today typical representatives in transaxle transversely mounted gearboxes.

GL-5:

Designates the type of service characteristic of hypoids in automotive axles under high-speed and/or low-speed, high-torque conditions. Gear oils according to API GL-5 are today preferably used in differentials.

First of all: It’s not our intention to make the decoupler look bad – we also fitted one, and think it’s a nice gadget – but we prefer to drive most of the time in 4WD-mode. You may ask why?