The other day I could examine another tiny part about the “oil-sucking” issue. My understanding is, that it’s a design failure, where the extrem high thermal expansion of the silicon oil causes the problem at low temperatures during winter. Therefore this problem would remain, also at new overhauled VC. And such a piece of evidence came across, but let’s begin in 2015…

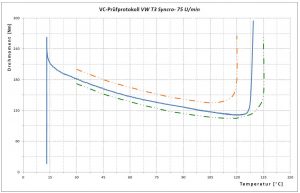

In 2015 I needed a fresh overhault VC from a test-rig to calibrate my own test-stand. So I ordered one from a well known Swiss guy. The chart of the ordered VC matched almost from the beginning perfectly with the one from my test-stand. I just had to find the best position of the temperature sensor.

|

|

As you can see, the chart fits perfectly in the +- 10% specification from Steyr-Daimler-Puch.

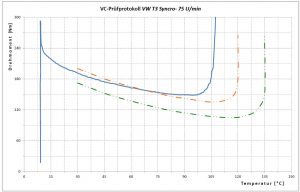

By accident I came across a used VC from the same Swiss based guy. The overhaulting happend a few years ago and the VC had a mileage of approximately 50tkm. And the chart below shows undoubtable a VC in the early state of “oil-sucking”.

|

|

I am sure that this VC was also once perfetley in the boundaries of Steyr-Daimler-Puch directly after overhauling. Anyone who knows how accurate the Swiss guy works, will not doubt that.

So it’s crystal clear, that also professional overhault VCs from a test-rig are not protected against oil-sucking. Daily drivers on a short distance (during winter) are very likely affected.

The newer VC-project of the T4 Syncro is not affected by this problem, although the inner components are also running in the gear oil of the transmission. But the VC of the T4 has also a special valve in the lid as our T3-VC does.