4WD

Why is the viscous-coupling not used in modern 4-wheel drive vehicles anymore?

Doesn’t a decoupler make more sense than the viscous-coupling?One of the last vehicles that came with the viscous-coupling was the “Porsche 911 Turbo” which was produced until 2008. According to the development engineers of Porsche, a controlled multi-plate coupling would have needed more weight and installation space than the viscous-coupling which was used. Furthermore the soft engaging characteristic of the viscous-coupling allowed for the powertrain to be dimensioned in a more compact way. So from a mechanical point of view the well-tried system of the viscous-coupling is definitely not obsolete.

However, the biggest advantage of the viscous-coupling is also its greatest weakness: It is a self-sufficient, self-regulating system which also works without complex electronics. In consequence this also means that you need to make a big additional effort if you want to combine it with electronic control systems. When it comes to this, the ABS brake system doesn’t cause any problems here, however electronic stability systems with various acronyms such as ESP, DSC, PSM and similar do cause problems. This is because brake interventions that are meant to be selective get transferred automatically to other tires as well by the viscous-coupling. Because ESP has been made mandatory for all new cars in 2011, we can expect the viscous-coupling to vanish as an all-wheel drive system.

I pursued this question in detail in my Bachelors Thesis.

What is the best all-wheel drive system then? Haldex? Torsen differential? xDrive?

To tell you right away: I personally have retrofitted my Syncro with a decoupler and I would no longer want to go without it, also for the simple reason that my favorite specialist garage doesn’t own a brake-test stand for 4WD vehicles. Removing the prop shaft every year to get the technical inspection done can get pretty tedious over time.

Moreover, it is kind of interesting to drive the first meters in unknown terrain decoupled. Just to get a rough impression about the difficulty level. It is always surprising how far you can do it without being a real Syncro. Last but not least the Decoupler is more practical in case the tow service is only able to raise the car in order to tow the car.

You may have already noticed that I mostly use the decoupler to switch off the 4WD. That’s because I want to be able to benefit from the advantages of a permanent all-wheel-drive system even in cases of changing road conditions. During the winter, when snowy and icy roads alternate with grippy asphalt, the viscous coupling can demonstrate its strength. The same goes for wet roads or slippery foliage in the fall.

The common practice to combine a hardened viscous-coupling which has sucked oil with a decoupler requires roads with low friction coefficients. However this mean that the 4WD can only be used off-road and let’s be honest, how many kilometers do you drive off-road and how many on the road in your Syncro?

Why needs the T4’s VC more time to activate compared with the older T3 Syncro?

Ranking the all-wheel drive systems in the sense of setting up a technological development chain (placing electronically controlled systems on top) is possible but useless. For instance mechanically simple all-wheel-systems with a decoupler and mechanical diff locks have a higher climbing power than modern designs with electrical controls- they all can’t exceed the simple system with a lock-out value of 100% .

However, electronically controlled systems have a slight advantage over self-regulating mechanical systems because the electronically controlled ones can usually distribute the driving force entirely (from 0-100%) between the axles.

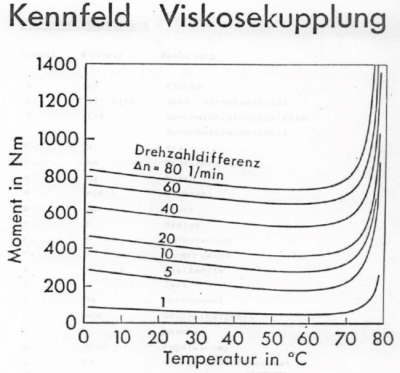

Self-regulating mechanical systems typically have narrower control limits. Thus, a Torsen-differential reaches only a lock-out value of 44%, while the lock-out value of a viscous-coupling in hump mode is specified with 98%.

However, todays widespread use of electronically controlled 4WD systems, is primarily due to the easy compatibility with electronic assistance systems such as ESP, ASR and ABS. These can be cost-effectively built on a common infrastructure like control units, wheel- and accelerating sensors.

The prop shaft of the T3 Syncro rotates roughly four times faster, than the prop shaft of the T4 Syncro. The longitudinal installation of the engine and the subsequent position of the differential ratio makes the difference. That's why the viscous moment of the T3 Syncro is always high enough to get the Bus out of a brake test stand at any temperature – despite the lower viscosity of the silicone oil.

With the T4 Syncro, the viscous moment is usually not always enough to lift the bus reliably out of a brake test stand. Typically, it works at the beginning with a cold VC, but often you get stuck at second try with spinning front wheels. The T4 Syncro’s 4WD design is generally "softer" and the average weight of the bus is simply higher.

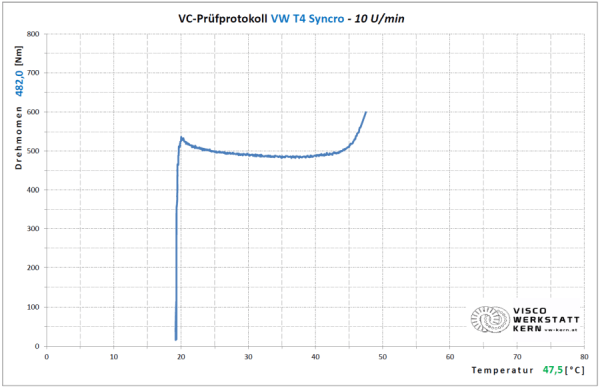

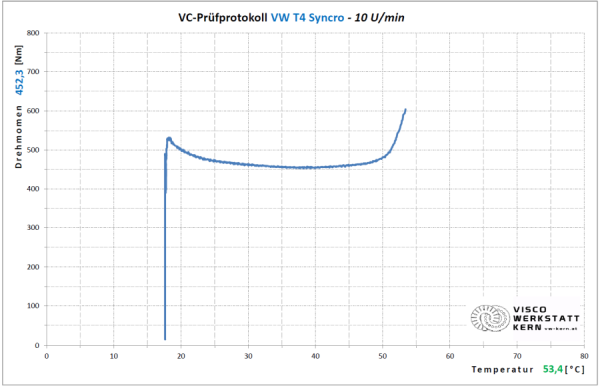

Therefore, the T4-VC must be warmed up by spinning front wheels, until hump-mode kicks in. That’s the moment where the bus is reliably pushed out of the brake test stand. Depending on ambient temperature, this can take several minutes, because a worn VC needs often more than 80 °C / 176 °F to switch into hump-mode. A fresh T4-VC got a hump temperature of just roughly 40 °C / 104 °F.

That's why we offer a harder setup (+ 25% / + 50%) for more ambitious off-road drivers among the T4 Syncro community. The aim is to get the T4 Syncro as easily out of a brake test stand as the T3 does. But a stiffer Sport-VC means also more (unwanted) tension on surfaces like tarmac.

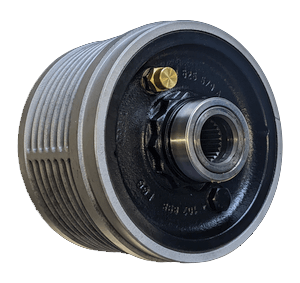

T3-VC

How can I test my viscous coupling?

What's the effect of inert gas in a viscous coupling?We recommend - like VW in their factory manual – the function test in a dynamometer. The test also works in a conventional brake test bench if the rollers turn freely when switched off.

• Bring VW T3 Syncro to operating temperature (highway)

• Drive the vehicle with the rear wheels on the rollers

• ATTENTION: Keep space in front of the vehicle!

• Engage G-gear and drive rear wheels at idle speed > the viscous coupling absorbs the speed differences between front and rear axles without locking. The bus remains in the test bench without the engine dying. (Otherwise the VC is extremely hardened)

• At accelerating from idle to 2000 - 3000 rpm, the bus should be pulled of the brake tester via the front axle. If the bus does not come out of the brake tester at all, then the VC is most likely failed open.

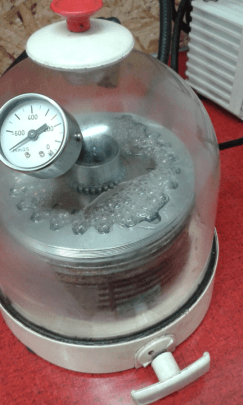

After removing the VC from the front differential we can put it on our test stand for detailed evaluation. Testing of old VCs in unknown condition on our test stand is always free of charge.

Why does viscous-coupling hardening appear so often in the T3-Syncro?

At temperatures around 150° C / 300 °F (local hot spots) the silicon oil reacts with the oxygen from the air in the viscous coupling. This oxidation process results in a gradual thickening of the silicon oil. For example, unequal worn tires are responsible for a permanent increased temperature level and therefore an early aging viscous coupling.

Degassing the silicon oil and the subsequent filling with inert gas increases the temperature resistance of such a viscous coupling to around 200 °C / 392 °F. Thereby the aging of the silicon oil is practically stopped. An on-road test over 10.000 km with unequal worn tires showed no wearing of the tested viscous-coupling.

The much more heat-resistant inert gas VC can handle unequal worn tires, high speed or intensive off-road use much easier.

Isn’t the "oilsucking" a result of an overheating viscous-coupling?

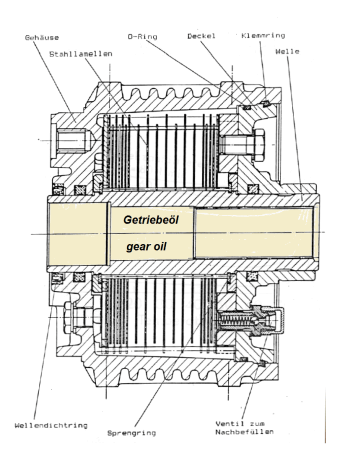

First of all we have to distinguish between a gradual hardening and an extreme hardening. Gradual hardening is a result of aging silicone oil (oxidation), which leads to the thickening of the fluid. Silicone oils with high zero viscosity (of up to 300k) are more vulnerable to this and were therefore only used in the early days of the test phase of the viscous-coupling.

The more common problem, namely that of extreme hardening, is a result of a construction fault. The extreme hardening of the coupling only occurs when the viscous-coupling has sucked gear oil from the front transfer case. The problem of “oilsucking” was discovered at the end of the 1980s at Steyr-Daimler-Puch (SDP) and was consequently investigated in a special Diploma thesis.

The remarkable conclusion was the following: At wintery outdoor temperatures, a static vacuum forms in the viscous-coupling due to the high thermal expansion of silicone oil. This vacuum is enhanced during start-up. Because of the vacuum the viscous-coupling sucks in portions of gear oil in the cold-running phase and breaks over time. This problem does not depend on the mileage. However the results of this investigation came too late in the summer of 1990. Therefore SDP did not make any further effort in solving the problem.

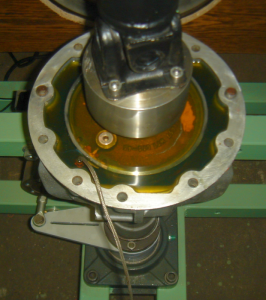

Our solution: A slight excessive pressure, applied to the lid of the viscous-coupling with help of a special valve, prevents the occurrence of an unwanted vacuum. However that means that in comparison to the original SDP-factory adjustment, we need to use a different filling quantity and an adjusted level of viscosity. Yet with a test stand, working out a new adjustment is a solvable task.

At VW-Kern, do you test each viscous-coupling in gear oil?

In various VW-Bus forums you’ll find the assumption that silicone oil is pressed out of the Viscous-coupling into the transfer case as a result of overheating, and that later in the cooling process, gear oil is sucked in. Yet only the first part of this rumor is true.

The truth is that the damage pattern of the inside-out quad-ring (or X-ring) does exist, however those viscous-couplings are always measured as “empty” on the test stand. A viscous-coupling which cannot change into Hump-mode anymore due to abrasion can indeed overheat. In this case the inner pressure of the viscous-coupling increases uncontrollably, and before it reaches the burst pressure of 100 bar the silicone oil is discharged into the transfer case. Then the viscous-coupling doesn’t produce any noticeable propulsion anymore- the Syncro is now permanently in 2WD-mode.

Overheated viscous-couplings are rather the exception. The overwhelming majority of viscous-couplings are destroyed by oil sucking.

Why are engine / tires / driving operation asked when ordering?

Test runs in gear oil are naturally complicated and therefore we use them mostly for defining basic tunings and for leak tests of new materials. As soon as the new basic tuning is found, those test runs aren’t necessary anymore.

For research purposes we also do longtime test runs under the influence of extreme conditions (low temperatures, vibrations) in gear oil.

Powerful third-party engines (TDI, EJ25 ...) are widely used in the T3 Syncro these days. However, the viscous coupling was once adapted to the original engine(s) and transfers only a specified maximum torque. An increase in performance automatically influences the original optimum torque distribution between front and rear axle (40/60). This means that only the rear axle gains more torque from a stronger engine if the VC isn’t adapted.

Practical experience has shown that this increases the tendency to dig in the rear axle on difficult terrain.

Depending on driving habits, it can make sense to adjust the VC to the higher torque of the engine. That’s why we ask customers about their specific vehicle data (engine / tires / area of application) to give them individual advice about the ideal VC setup.

Golf-VC

Which Golf Viscous Coupling (Standard / Sport / Super Sport) suits best for me?

Are the seals included?Our Standard VC comes with the same setup like the original from VW. This setup is still the first choice for on-road vehicles with original engine performance.

Compared to an old worn VC, the all-wheel drive activates much faster with our new Standard VC, since the hump temperature is reset to 40 °C. In addition we prevent the VC from premature aging, by filling it with an inert gas that increases the heat resistance of the silicone oil.

Our Sport VC is primarily intended for vehicles with a tuned engine in order to bring the additional power to the rear axle and ultimately to the road. The Sport edition is also aimed at the VW Golf Country, when the great-grandfather of all SUVs is also seriously challenged off-road, or is often operated with a heavy trailer.

Additional tension in the drive train is practically imperceptible with the Sport-VC during road operation. We prevent the VC from premature aging, by filling it with an inert gas that increases the heat resistance of the silicone oil.

The Super-Sport VC is reserved for top-class vehicles with a 6-cylinder engine (VR6) and only makes sense for heavily tuned engines from around 250 - 300 hp. In practice, our Super Sport Visco achieves reaction times in ¼ mile races that come close to Haldex conversions.

On tarmac, the Super-Sport VC shows noticeable tension in the drive train, which is reflected in increased tire wear. We prevent the VC from premature aging, by filling it with an inert gas that increases the heat resistance of the silicone oil.

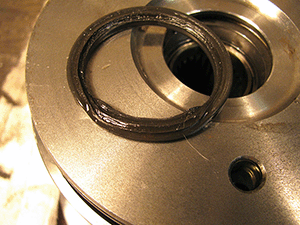

How much do the 3 different variants cost? (Standard/ Sport / Super-Sport)More details can be found in our installation instructions.

The following parts are supplied with the VC:

• 020 301 189 T / shaft seal 65,2 x 50 x 10

• N 902 995 001 / O – Ring 28 x 2

• G 055 128 A1 / grease (replaces G 052 128 A1)

• business cards + VW-Kern sticker

How can I test my viscous coupling?

What’s the effect of inert gas in a viscous coupling?

We recommend - like VW in their factory manual – the function test in a dynamometer. The test also works in a conventional brake test bench if the rollers turn freely when switched off.

• Test the VC in cold condition

• Drive the Syncro with the front wheels on the rollers

• ATTENTION: Keep space in front of the vehicle!

• Engage first gear and drive front wheels at idle speed > the viscous coupling absorbs the speed differences between front and rear axles without locking.

• At accelerating from idle to 1500 - 2500 rpm, the bus should be pulled of the test stand via the rear axle.

• If the front wheels have to spin for a long time before the bus pulls of the test stand, the viscous torque of the VC has decreased due to aging of the silicone oil.

After removing the VC from the front differential we can put it on our test stand for detailed evaluation. Testing of old VCs in unknown condition on our test stand is always free of charge.

Is the Golf viscous coupling also affected by “oil-sucking”?

At temperatures around 150° C / 300 °F (local hot spots) the silicon oil reacts with the oxygen from the air in the viscous coupling. This oxidation process results in a gradual thickening of the silicon oil. For example, unequal worn tires are responsible for a permanent increased temperature level and therefore an early aging viscous coupling.

Degassing the silicon oil and the subsequent filling with inert gas increases the temperature resistance of such a viscous coupling to around 200 °C / 392 °F. Thereby the aging of the silicon oil is practically stopped. An on-road test over 10.000 km with unequal worn tires showed no wearing of the tested viscous-coupling.

The much more heat-resistant inert gas VC can handle unequal worn tires, high speed or intensive off-road use much easier.

Which maximum torque can the Golf viscous coupling transfer?

As the inner parts of the Golf viscous coupling are part of the differential’s oil system, the problem of “oil-sucking” could theoretically also occur.

„Oil-sucking“ is caused by a vacuum inside the VC, which appears at low temperatures in winter due to the high thermal expansion of silicon oil. During start up, the VC absorbs gear oil in portions and slowly breaks down. This design flaw is independent of mileage.

Since the Golf Syncro's viscous coupling already got a valve installed in the steel cover, which prevents the formation of a vacuum, the VC is not affected by “oil-sucking”.

The maximum transmission torque of the viscous coupling is achieved in hump mode, when the steel plates are pressed together due to the abrupt increase in pressure. Unfortunately, we got no specific data for the maximum hump torque.

For the viscous coupling of the Golf Syncro exists a transmission curve, where the hump torque is scaled up to 1400 Nm at 80 °C / 176 °F. It is not known if the maximum (hump torque) occurs here at the same time, or if it can be even higher.

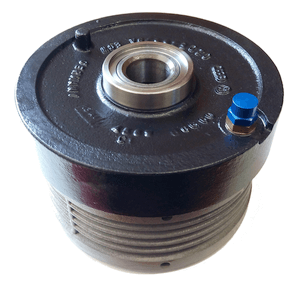

T4-VC

Which T4 Viscous Coupling (Standard / Sport / Super Sport) suits best for my bus?

Are the shaft sealing rings included?Our Standard VC comes with the same setup like the original from VW. This setup is ideal if the bus is mainly used on-road and the all-wheel drive is only intended as a starting aid on icy roads and used for light off-roading.

Compared to an old worn VC, the all-wheel drive activates much faster with our new Standard VC, since the hump temperature is reset to 40 °C. In addition we prevent the VC from premature aging, by filling it with an inert gas that increases the heat resistance of the silicone oil.

The driving forces are distributed in a 80 : 20 ratio between front- and rear-axle with the Standard VC. For buses without ABS, this is the only possible setup without affecting the braking stability of the vehicle.

With our Sport VC, the T4-Syncro becomes a real all-wheel drive vehicle for the first time. This setup is the first choice if the bus should gain the ability to operate in rough terrain, but is mainly driven on-road. The Sport VC reacts much faster and activates independently from its temperature - so it does not have to be "warmed up" first.

Additional tension in the drive train is practically imperceptible with the Sport-VC during road operation. We prevent the VC from premature aging, by filling it with an inert gas that increases the heat resistance of the silicone oil. With the Sport-VC, driving forces are distributed in a 65 : 35 ratio between front- and rear-axle .

Our Super-Sport VC is designated for Syncros, which are mainly used off-road and rarely on asphalt. Examples include forest vehicles or pure expedition vehicles (crossing Africa). During the development, we cooperated with a forestry contractor whose T4-Syncro Dokas has to make its way through rough forest terrain on a daily basis.

On tarmac, the Super-Sport VC shows noticeable tension in the drive train, which is reflected in increased tire wear. Compared with the Sport VC, the Super-Sport edition shows just little advantage when it comes to off-roading. The aim of the development was rather to maximize the lifespan of the VC in extreme use, without considering roadworthiness.

Since the wear-intensive hump mode of the Super Sport VC applies rarely only, the VC is extremely long lasting. In addition we prevent the VC from premature aging, by filling it with an inert gas that increases the heat resistance of the silicone oil.

The driving forces are distributed in a 60 : 40 ratio between front- and rear-axle with the Super Sport VC. A Super-Sport VC may also be useful for buses with a modified, shorter gear ratio (which automatically reduces the effectiveness of the VC), even if the bus is mainly used on-road.

How much do the 3 different variants cost? (Standard/ Sport / Super-Sport)More details can be found in our installation instructions.

The following parts are supplied with the VC:

• 02D 525 597 / shaft seal 71x7

• 02D 525 583 / shaft seal VC

• G 055 128 A1 / grease (replaces G 052 128 A1)

• business cards + VW-Kern sticker

How can I test my viscous coupling?

What’s the effect of inert gas in a viscous coupling?

We recommend - like VW in their factory manual – the function test in a dynamometer. The test also works in a conventional brake test bench if the rollers turn freely when switched off.

• Test the VC in cold condition

• Drive the VW T4 Syncro with the front wheels on the rollers

• ATTENTION: Keep space in front of the vehicle!

• Engage first gear and drive front wheels at idle speed > the viscous coupling absorbs the speed differences between front and rear axles without locking.

• At accelerating from idle to 1500 - 2500 rpm, the bus should be pulled of the test stand via the rear axle.

• If the front wheels have to spin for a long time before the bus pulls of the test stand, the viscous torque of the VC has decreased due to aging of the silicone oil.

After removing the VC from the front differential we can put it on our test stand for detailed evaluation. Testing of old VCs in unknown condition on our test stand is always free of charge.

Which type of silicone oil is used in the T4 Syncro?

At temperatures around 150° C / 300 °F (local hot spots) the silicon oil reacts with the oxygen from the air in the viscous coupling. This oxidation process results in a gradual thickening of the silicon oil. For example, unequal worn tires are responsible for a permanent increased temperature level and therefore an early aging viscous coupling.

Degassing the silicon oil and the subsequent filling with inert gas increases the temperature resistance of such a viscous coupling to around 200 °C / 392 °F. Thereby the aging of the silicon oil is practically stopped. An on-road test over 10.000 km with unequal worn tires showed no wearing of the tested viscous-coupling.

The much more heat-resistant inert gas VC can handle unequal worn tires, high speed or intensive off-road use much easier.

What is the right amount of silicone oil for the T4 VC?

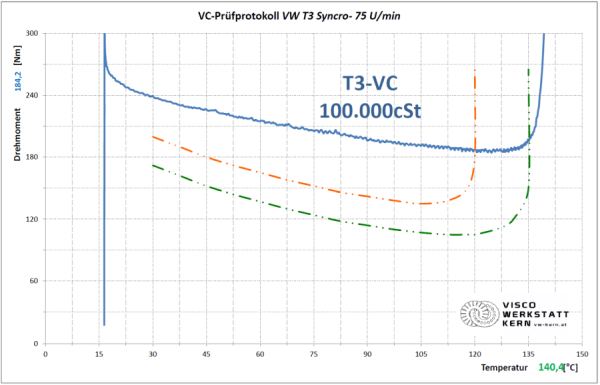

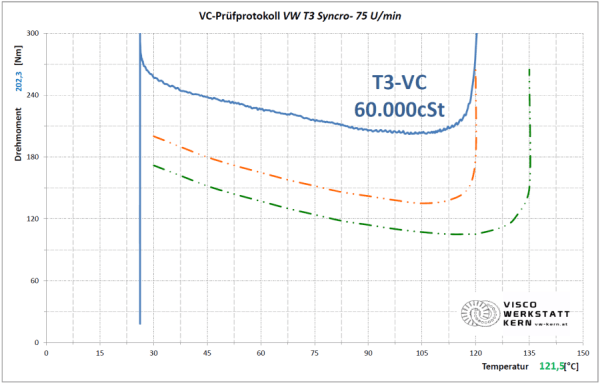

The T4 Syncro's external viscous coupling (originally developed for the Golf 2 - Syncro) uses silicone oil with a viscosity of 100,000 cSt - if necessary, other viscosities are added for fine tuning.

For example, if the viscous coupling has been filled with a to large air bubble, then the curve will fall as a whole. This means a 100,000 cSt oil can behave like a 60,000 cSt oil, if you underfill the VC and vice versa.The power transmission characteristic is not just based on viscosity, but also by the residual air inside the VC. As soon as the plates start to rotate, the air bubble in the VC mixes as small bubbles in the silicone oil. These small bubbles act as imperfection and reduce the shear strength of the silicone oil - or rather the dynamic viscosity.

The mixing process can be observed at the initial spike during startup in the test stand, which then drops very quickly. Therefore, the provisional test of a viscous coupling with a torque wrench is not meaningful about the dynamic processes in the vehicle.

Why are Sport-VCs only available for T4 buses with ABS?

Due to manufacturing tolerances (the fluctuating thickness of the plates is the biggest influencing factor) every viscous coupling needs a specific filling quantity. The filling level adjusts the hump temperature of the viscous coupling, which is brand-new at about 40 °C / 104 °F.

The compensation of the manufacturing tolerances take up to +/- 15g difference in filling quantity. The filling level is thus a determinant that must be adapted to the specific viscous coupling. In the diagram below, a viscous coupling was undertaken a test run and after complete cooling, just one gram of silicone oil was drained off. The weight difference was checked by means of some scales.

Afterwards a test run revealed that even a small deficit of only one gram of silicone oil increases the hump temperature by about 7.5 °C / 13.5 °F.

Due to coupling of axles, a viscous coupling is also active during braking, not only while driving. The Sport-VC thus, increases the braking torque on the rear axle on buses without ABS automatically. On a straight lane with equal friction, this is an advantage and even leads to a lower braking distance, because of the optimal distribution of braking force.

However, there are special situations (cornering, different friction ...) in which an overbraking of the rear axle by a Sport-VC is thinkable. The principle of controlled braking behavior says, that the rear axle must not block under no circumstances bevor the front axle. Otherwise the vehicle will lose its stability and hurls uncontrollably. Although the vehicle loses its steering ability due to blocking front wheels, the rear wheels can absorb lateral forces and keep the vehicle in the lane.

Unfortunately, we cannot simulate the influence of the Sport-VC in order to give general instructions. Practically, brake tests in the safe environment of a test site would have to be performed with the specific vehicle in order to work out a new setup.

That's why we offer Sport-VCs only for T4 buses with ABS, as they have a freewheel in the rear differential. The freewheel automatically opens the drive train in braking and coasting mode. Thereby the VC simply cannot exert any (negative) influence during braking on buses with ABS.

Entgasen

Entgasen

installation material

installation material

mounting material

mounting material