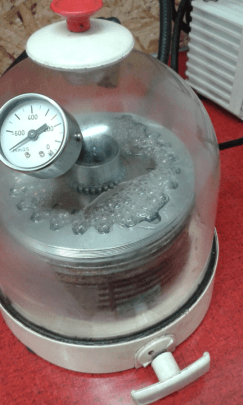

Testbed

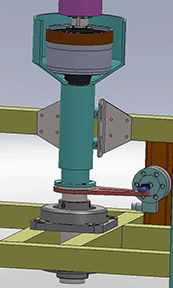

• In order to closely investigate the problem of "oilsucking",

realistic test runs of the viscous-coupling in gear oil should be possible.

• Test runs concerning the service life, done for several hours at a

constant temperature level are only possible in a cooling medium (e.g. gear oil).

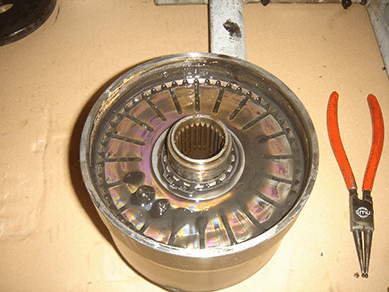

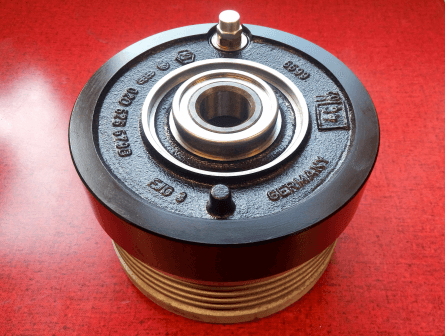

Overhaul

T3 Viscous Coupling

Rebuilding always happens according to the manufacturer’s instructions, which allow for a tolerance band of ±10% regarding the characteristic curve. Deviating from its original state, a special valve is additionally screwed into the case cover in order to solve the problem of oilsucking:

In addition, the viscous coupling is being degassed by a vacuum pump and filled with an inert gas to improve the heat resistance of the silicon oil.

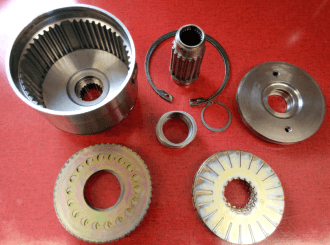

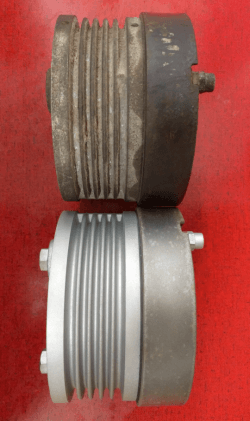

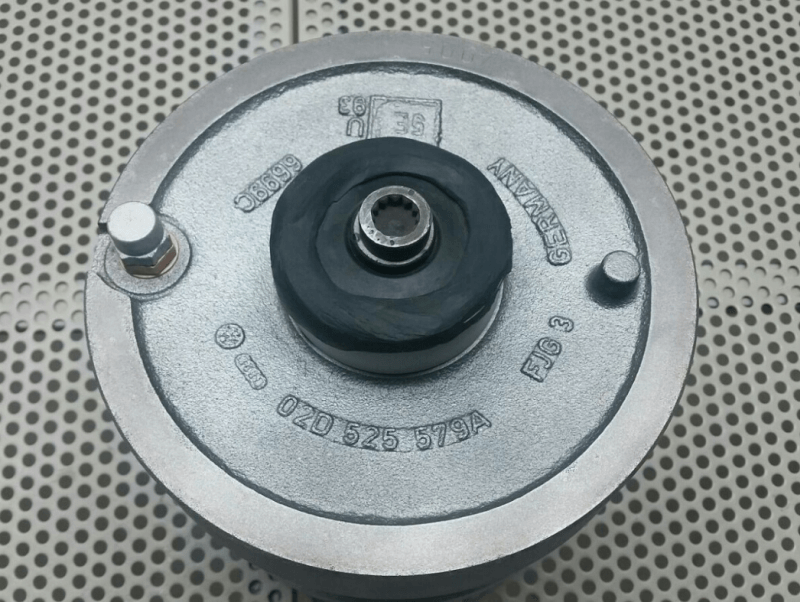

T4 / Golf Viscous Coupling

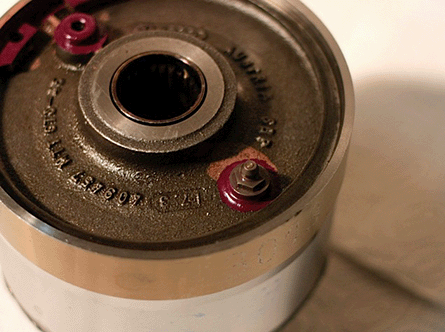

In order to remove rust and dirt, the VC is carefully blasted and protected against corrosion with a hard-wearing paint.

Furthermore we improve the VC by replacing the rust-prone

shaft bushing

with one out of stainless steel specially made for us. We use a Speedi-Sleeve repair sleeve from SKF to restore the original surface on the shaft end of the Golf VC.

In addition, the viscous coupling is being degassed by a vacuum pump and filled with inert gas to improve the heat resistance of the silicon oil.

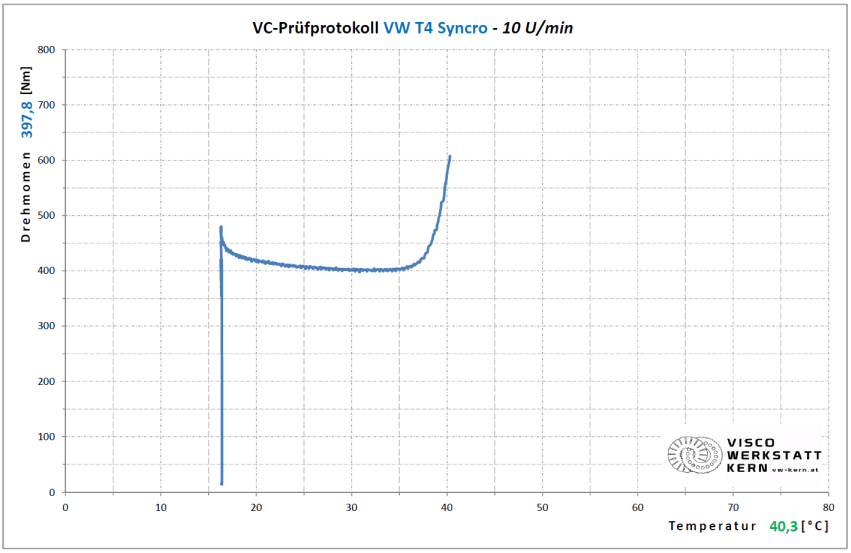

The overhauling of the VC is based on data that we could gain by measuring factory-new viscous couplings. We particularly pay attention to the correct setting of the hump temperature, which should be around 40 °C.

Since the

factory setup

of the T4 / Golf VC is rather designed as a traction aid on ice and snow, than for off-road purposes, we also offer harder setups for more ambitious off-road drivers.

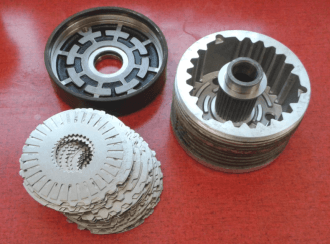

Main Components

An overview of the mechanical construction:

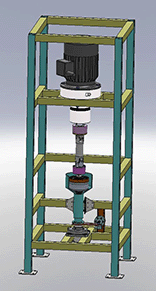

• An asynchronous motor fed by a frequency converter drives a planetary gear

• The hub of the viscous-coupling is powered by a drive shaft

• The analysis is done by a highly sensitive load cell following the principle of measuring the reactive torque.

Recorded figures

• Case temperature of the viscous-couplingThanks to the vertical build of the test stand, it is also possible to conduct realistic test runs of the viscous-coupling in gear oil.

• Transmitted torque

• Measurement of the inner pressure (currently planned)

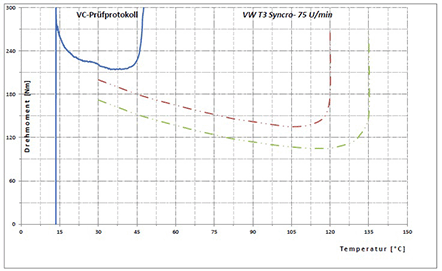

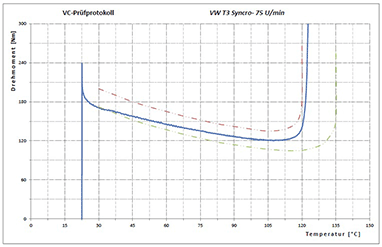

Extrem hardend VC

Extrem hardend VC Perfectly working VC

Perfectly working VC

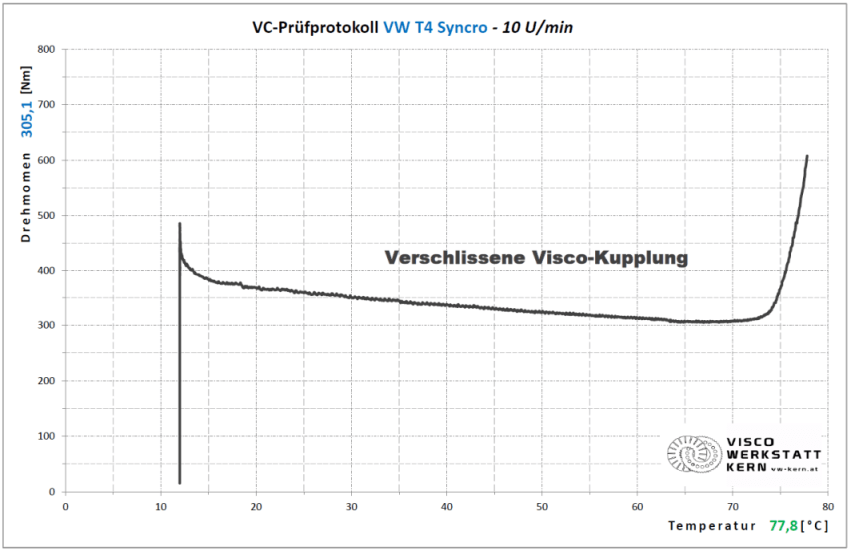

Worn VC

Worn VC Brand new VC

Brand new VC