History

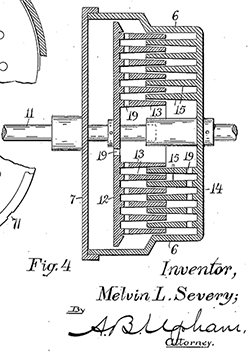

As early as 1917, the American inventor Melvin L. Severy got a patent granted for a viscous fluid coupling. However, at this time the only oils available were viscous oils of mineral origin, which are badly suited for transferring high torques. That’s because on the one hand, viscosity decreases when temperature rises, and on the other hand, higher temperatures cause disintegration.

Only the wonders of modern chemistry made the breakthrough of the idea finally possible. Now silicone oil could be produced synthetically. Therefore a fluid was available which is resistant to highest temperatures and also loses very little of its viscosity when warmed. Even so, using silicone oil is at best a compromise solution, since its pseudoplasticity is actually unwanted.

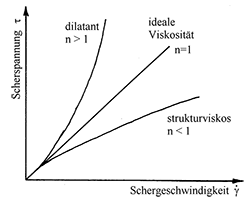

Thus higher difference revolution speeds (shear rates) cause an apparent decrease in viscosity, followed by a digressive increase in the transferrable drive torque. The opposite behavior, called “dilatant”, would be ideal for the use in a viscous coupling. Sadly there are no known dilatant fluids which react similarly chemically stable to silicone oil when used under the special strains of a viscous coupling.

The basic idea was taken up again by “Harry Ferguson Developments” in the 70s and the modern viscous coupling, using silicone oil as a transfer medium, was born. In the automotive industry, the viscous coupling was first used primarily as torque converter, vibration damper and as viscous cooling fan. In the beginning of the 80s, new applications in 4WD vehicles were found after lots of development work:

The Viscous limited slip diff (VLSD):

Speed-sensitive differential lock

The Viscous-Transmission:

A middle differential and a differential lock between front and rear axle

By the way the first vehicle with a viscous-transmission was not the VW-T3 Syncro but the AMC Eagle, which is said to be the precursor of nowadays’ SUVs. It was produced between the years 1979 and 1987.

Functionality

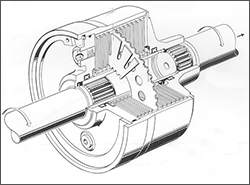

The free inner volume of a viscous coupling is filled to about 90% with silicone oil.

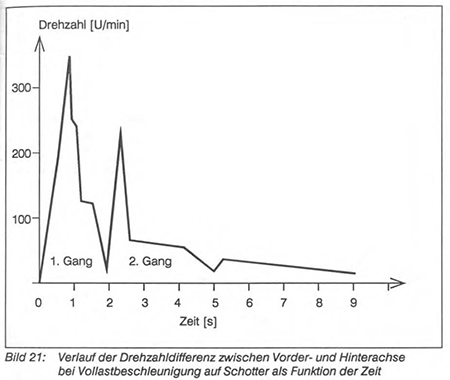

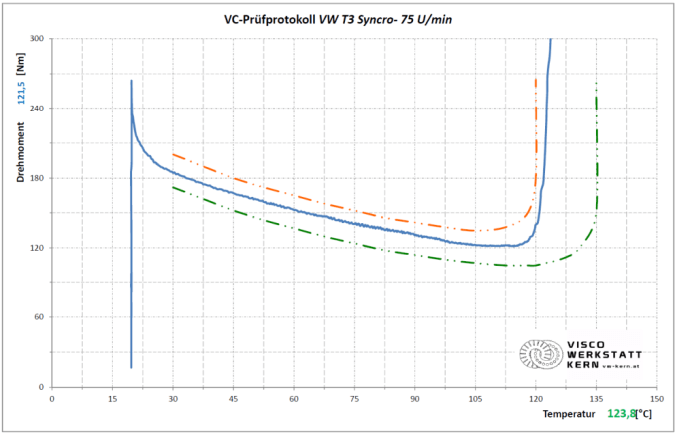

The input variable for the transferrable drive torque in the viscous coupling is exclusively the varying differential speed between the two axles. Concerning the transmission behavior we have to distinguish between two different modes. In principle, a viscous coupling first goes through the "Viscose-mode" and can switch to the so called "Hump-mode" in case of continuous stress.

Viscose-mode:

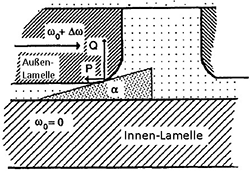

FLUID FRICTION

As soon as the external and inner plates rotate at different speeds, cohesion causes inner friction inside the molecules of the silicone oil, which tries to equalize the differential speed again. In this process the silicone oil is exposed to additional shearing forces at the holes and slots between the plates which are rotating against each other.

Silicone oils are pseudoplastic fluids, which means their viscosity decreases with increasing shear stress. This causes a digressive transmission behavior in the drive torque. The transferred torque depends mainly on the momentary viscosity of the silicon oil and the geometry of the set of plates. Then again the momentary viscosity depends on the base viscosity, the temperature and the shear stress.

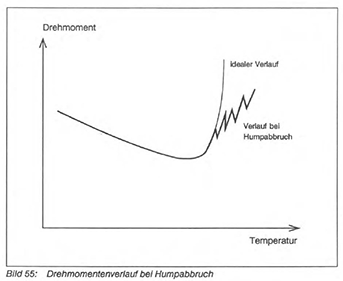

Hump-mode:

SOLID STATE FRICTION

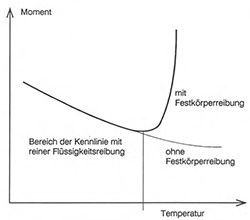

The inner friction that occurs in Viscose-mode causes the silicone oil to warm up. Since silicone oils have high thermal expansion (about fourty times that of aluminum), the inner pressure rises inside the hermetically sealed viscous coupling. During this process it’s mostly the degree of filling (e.g. 90%) of the viscous coupling which influences the speed at which the pressure increases. In case of a steady differential speed, the contained air therefore gets more and more compressed and creates a solution with the silicone oil, until an effective filling level of 100% is reached. In this state the inner pressure rises abruptly, so that further energy input would destroy the viscous coupling, which is designed for a maximum inner pressure of approx. 100 bar. This causes the viscous coupling to go into Hump-mode. In the past the Hump effect was thought to be a dilatant behavior of the silicone oil. However the Hump effect has nothing to do with sudden changes in viscosity since silicone oil is not dilatant but instead the opposite, namely pseudoplastic.

If the gaps become too narrow, the silicone film tears, causing mechanical friction between the plates. Hence the transmitted torque suddenly increases, whereby the differential speed quickly declines. On the road this means that a vehicle that got stuck can now either be freed or that the motor dies. The temperature falls and the viscous coupling changes back to Viscose-mode. The Hump-mode is meant for a momentary increase of traction in extreme situations, but it is also a constructive self protection mechanism of the coupling from overheating.

T3 VC flaws

The overwhelming majority of old T3 viscous couplings show the same defect during test:

That of extreme hardening.

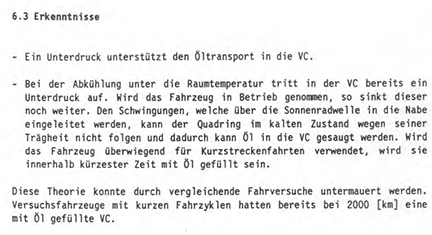

However this very common “extreme hardening” of the T3-Visco is no sign of aging but a design flaw. This specific extreme hardening of the T3-Visco only occurs when the viscous coupling has sucked gear oil from the front differential. The problem of “oilsucking” was noticed at Steyr-Daimler-Puch (SDP) in the late 80s, which is why it was also investigated in a diploma thesis.

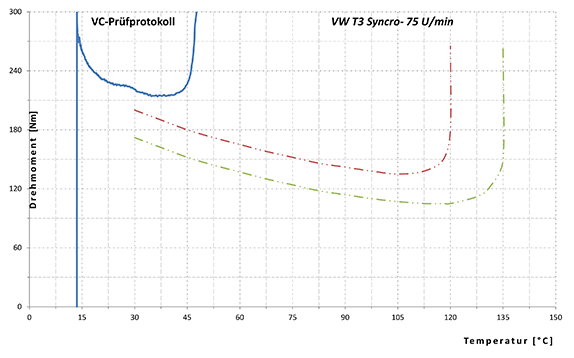

The remarkable conclusion was the following: At wintery outdoor temperatures, a static vacuum forms in the viscous coupling due to the high thermal expansion of silicone oil. This vacuum is enhanced during start-up. Because of the vacuum the viscous coupling sucks in portions of gear oil in the cold-running phase and breaks over time. This problem does not depend on the mileage. In short-distance operation an extreme hardening of the viscous coupling can already happen after 2000 km (approx. 1243 miles). However the results of this investigation came too late in the summer of 1990. Therefore SDP did not make any further effort in solving the problem.

Test setup:

A simple test setup with a manometer shows the virulence of the issue.Our approach:

In order to prevent the “oilsucking” caused by the vacuum, the viscous coupling is filled through a special valve.Comparing it with the SDP factory adjustment back then, nowadays we need another filling quantity and an adjusted viscosity. Yet with help of a test bench, working out this modification is a solvable task.

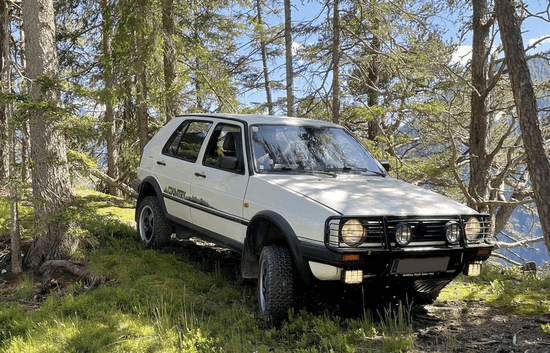

Golf VC Flaws

TOO SOFT FOR HIGHER PERFORMANCE

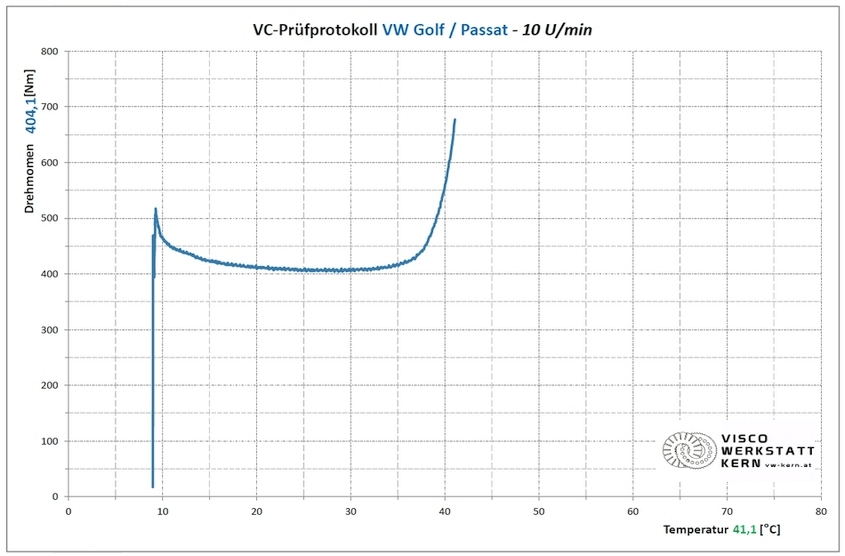

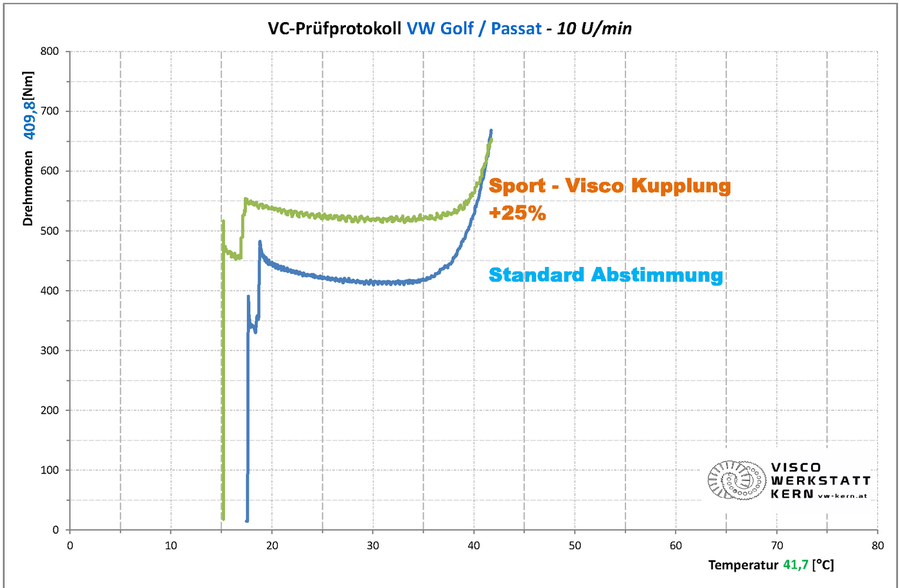

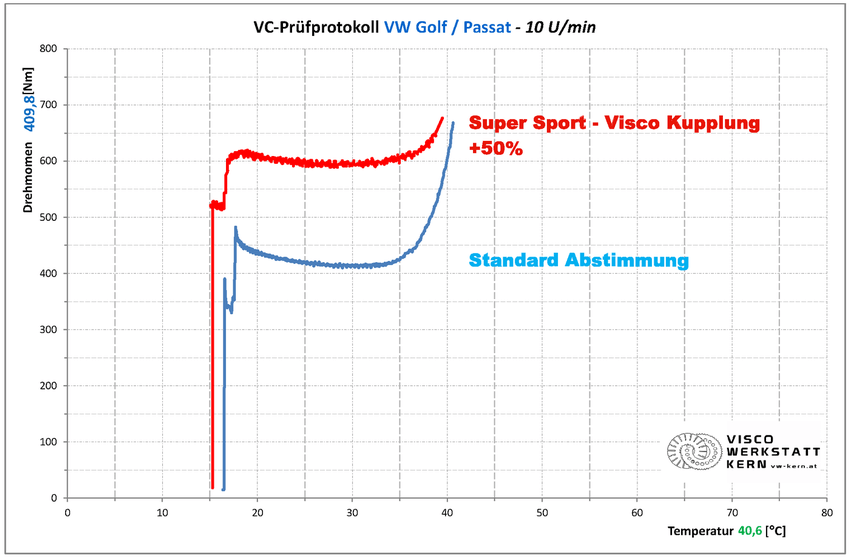

The Golf Syncro's viscous coupling is relatively durable and robust. The problem areas overlap with the similar constructed viscous coupling of the T4 Syncro, albeit to a much lesser extent. A need for action usually arises due to a higher increase in performance or frequent off-road use for which the all-wheel drive concept of the Golf was not intended.With 400 Nm @ 10 rpm, the Golf VC comes practically with the same setup as the T4 VC. However, the Golf's cardan shaft does not rotate faster than its drive shafts, since the angle drive with 21/20 teeth has a neutral gear ratio of 1.05. In comparison, the cardan shaft of the T4 rotates almost twice as fast, with a gear ratio of 0.63 with 17 to 27 teeth. As a result, the viscous-coupling of the T4 transmits almost twice as much power (= torque x speed). The drive train of the Golf VR6-Syncro was adapted to the higher engine power of the 6-cylinder in the same way. The cardan shaft, and thus also the viscous coupling, rotates around 40 % faster (16/21) on the VR6 Syncro than on the conventional 4-cylinder Golf Syncro. The adaptation of the VC to engine power and vehicle weight was never made via torque, but via the speed of the viscous coupling on different VW Syncro vehicles.

We offer a Sport VC for tuned Syncros, which reacts much faster than the standard VC. The 3 different setups (standard, sport, super sport) are described in detail in the FAQ area for the Golf. This should make the selection for your own vehicle easier.

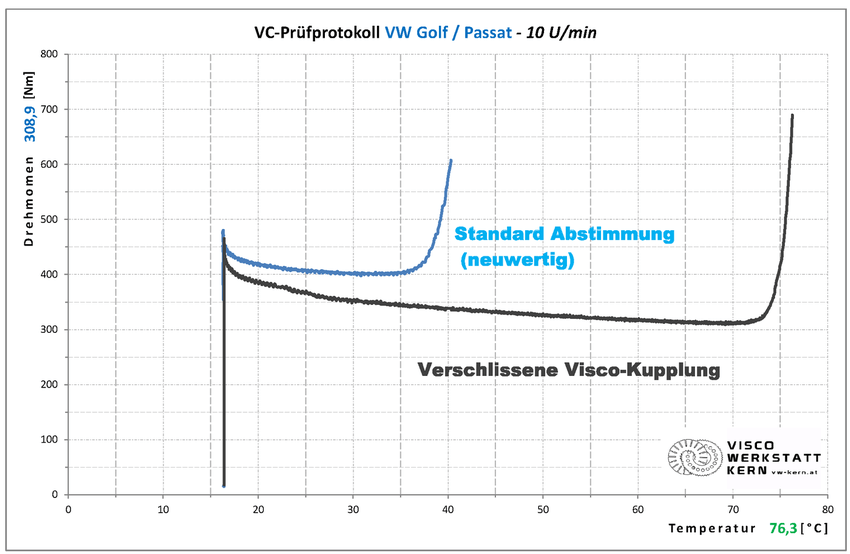

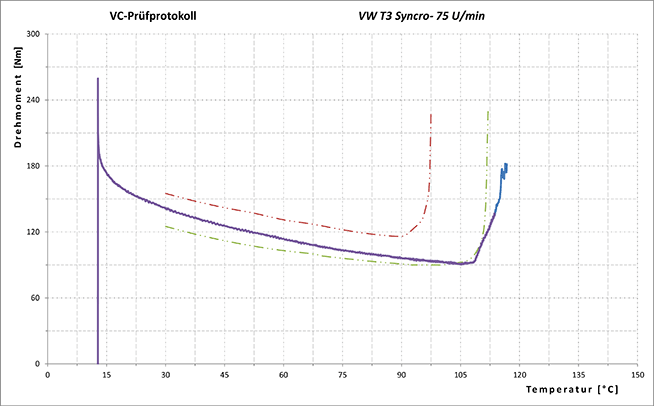

Increased Hump temperature

In tough off-road use, the automatic locking function (hump mode) is much more active. The occurring high temperature peaks in Hump-mode cause premature wear of silicone oil. Which results in an increased Hump temperature. With a new viscous coupling, the Hump temperature is about 40 °C. Due to heavy use the silicone oil can wear out, the Hump temperature can rise to 80 ° C and higher.That's why we set the Hump temperature carefully to the lower tolerance limit. In addition, we fill the viscous coupling with inert gas instead of conventional air to increase the temperature resistance of the silicone oil.

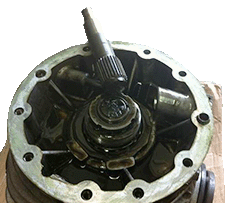

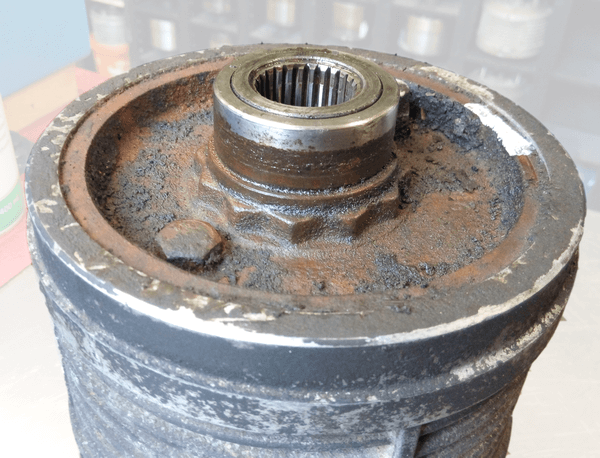

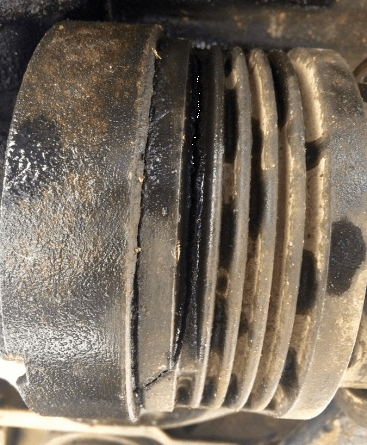

RUSTY SHAFT END

After more than 30 years, the shaft end of the Golf Visco, that seals the differential, is usually badly damaged. Because of the harsh environmental conditions on the vehicle underbody, the shaft bushing tends to get rusty. Over time the corrosion creeps down to the lips of the shaft seal, which often starts an unnoticed leakage of gear oil from the differential. Due to the rotation and centrifugal forces, it’s furthermore hard to recognize the constant oil loss.

Many rear differential damages have their origin here. The practical experience has shown that the oil level in rear Syncro differentials are almost always too low.

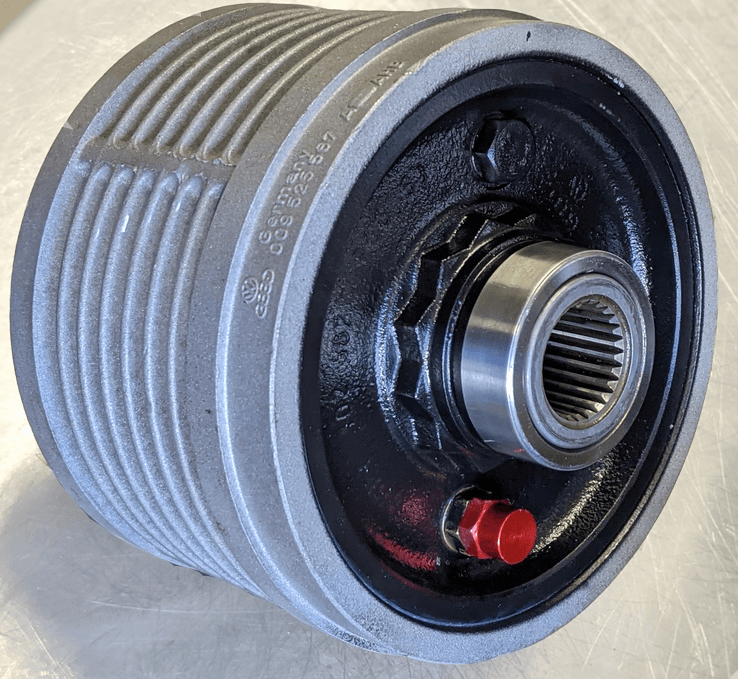

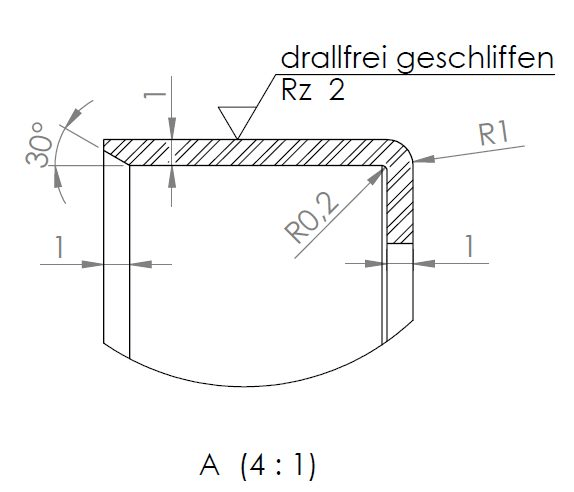

We fix this flaw by pressing a stainless steel

SKF repair sleeve

onto the rusty shaft end. Their surface is wear-resistant and machined without twist (0° ±0.05), the roughness Ra is between 0.25 and 0.5 μm. The repair sleeve thus offers a much better sliding surface for the sealing lips of the shaft seal than the original sliding surface on the shaft end.

T4 VC flaws

Soft characteristic

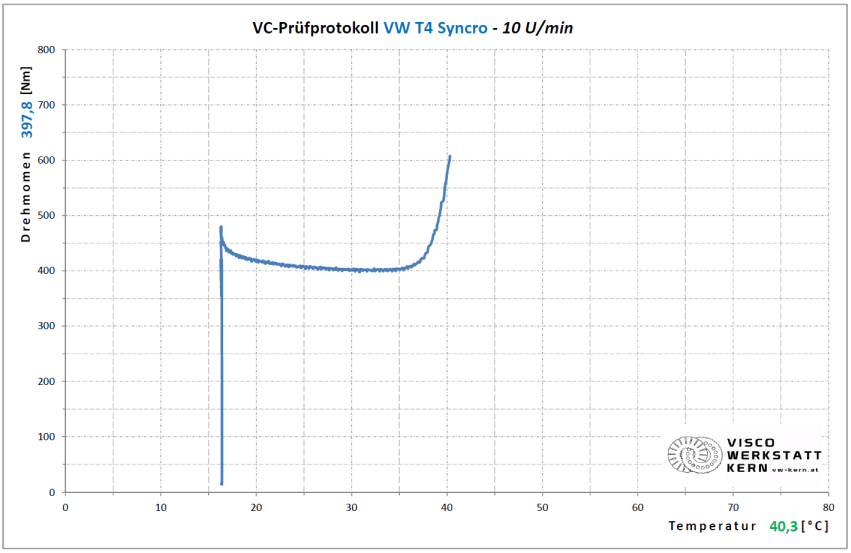

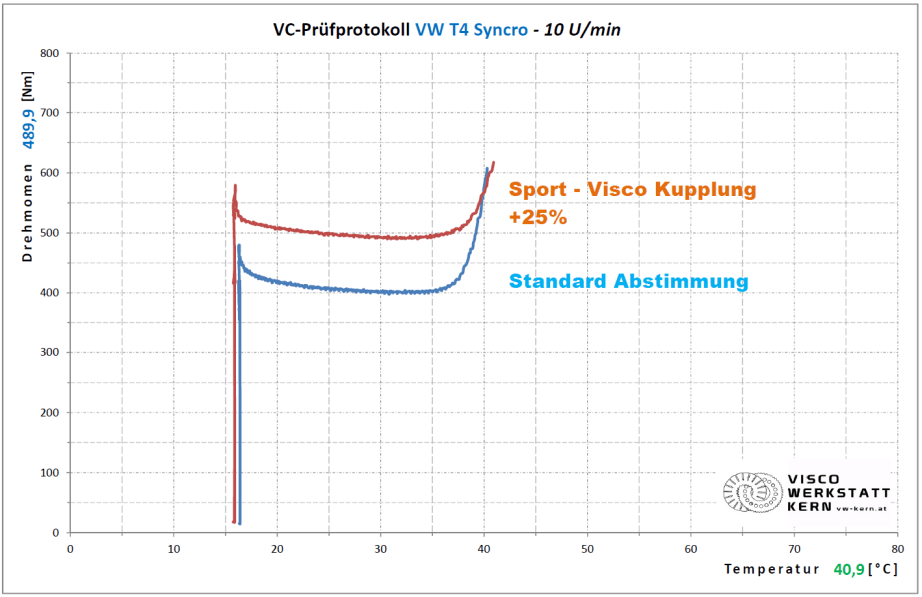

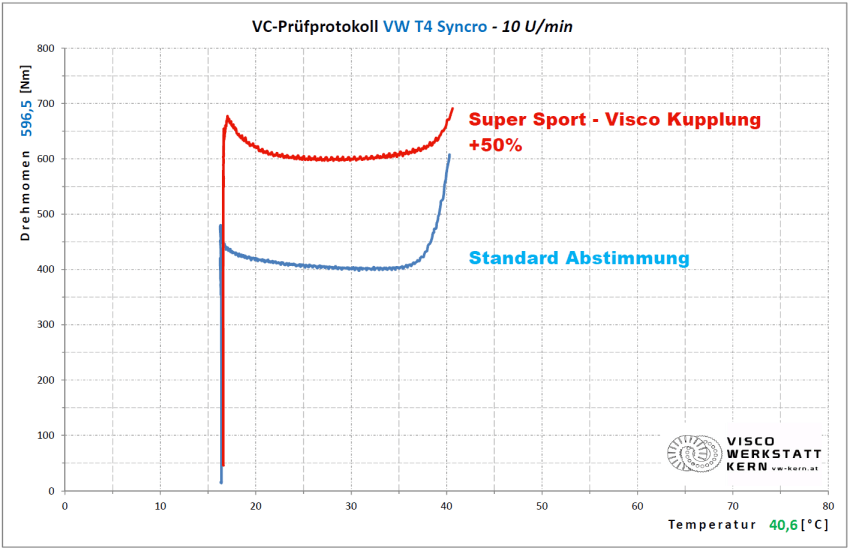

Although the T4 Syncro's viscous coupling has no design flaws (unlike the T3 Syncro), it is often at its limit when it comes to rough terrain.The factory adjustment of the viscous coupling, which transfers roughly 400 Nm (@10 RPM) is enough for icy roads in winter, but overstressed in hard terrain like mud, sand and deep snow.

Especially heavy and tuned vehicles suffer from extended front wheel spin, until the rear axle slowly engages. Usually one is then already stuck.

Therefore we also offer Sport-VCs for tuned and heavy vehicles with ABS , which reacts much faster than the standard viscous coupling. The 3 variants (Standard, Sport, Super-Sport) are described in detail in our FAQ to make the selection for your own bus easier.

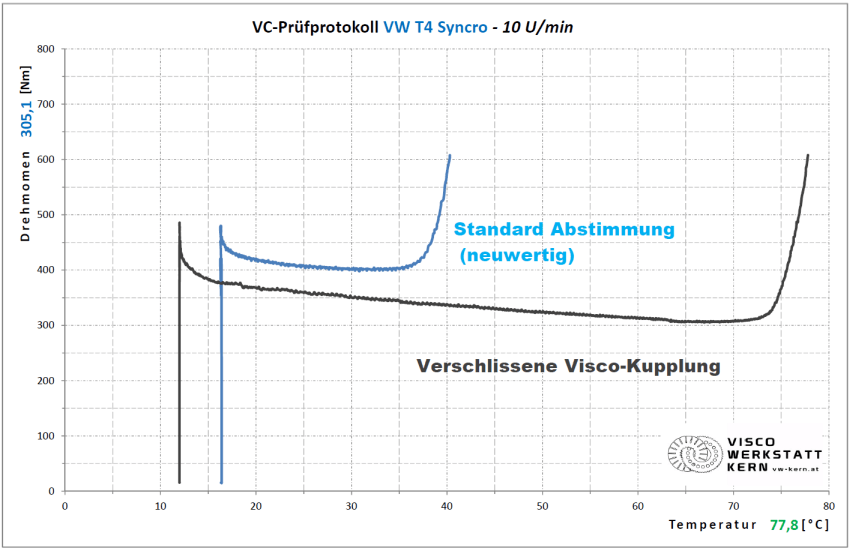

Increased Hump temperature

Unlike the fast spinning viscous coupling of the T3 Syncro, the T4 Syncro uses the VC’s automatic lock function (Hump-mode) much more frequently while off-road driving. The occurring high temperature peaks in Hump-mode cause premature wear of silicone oil. Which results in an increased Hump temperature. With a new viscous coupling, the Hump temperature is about 40 °C. Due to heavy use the silicone oil can wear out, the Hump temperature can rise to 80 ° C and higher.Rusty shaft bushing

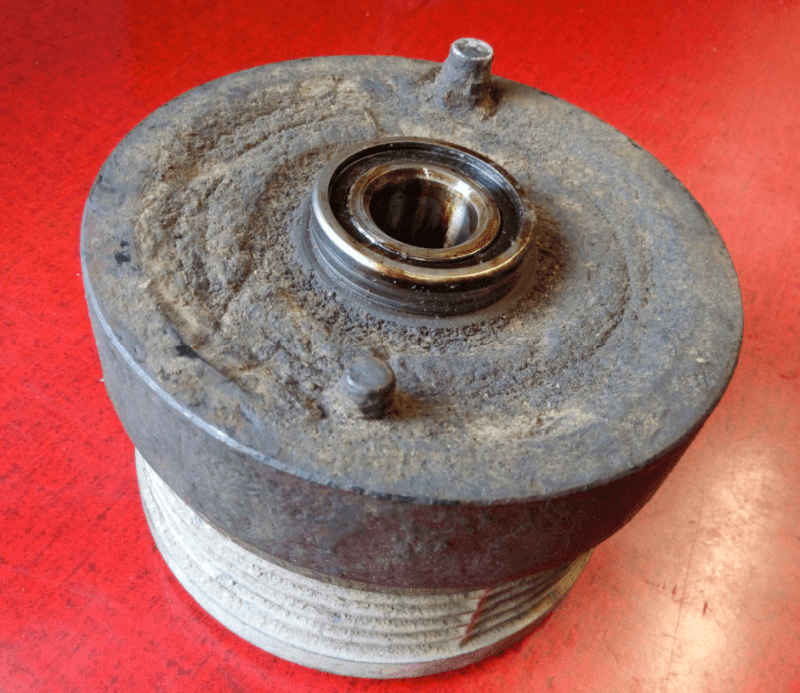

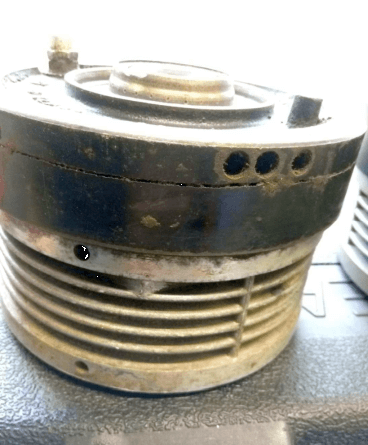

The most serious flaw relates to the bare, inconspicuous shaft bushing on the steel cover of the viscous coupling. Because of the harsh environmental conditions on the vehicle underbody, the shaft bushing tends to get rusty. Over time the corrosion creeps down to the lips of the shaft seal, which often starts an unnoticed leakage of gear oil from the differential. Due to the rotation and centrifugal forces, it’s furthermore hard to recognize the constant oil loss.

Many rear differential damages have their origin here. The practical experience has shown that the oil level in rear differentials of T4 Syncro’s are almost always too low. In some cases the differentials were nearly dry.

We fixed this flaw by replacing the rust-prone standard bushing with one especially made for us from stainless steel. The surface of the stainless steel bushing is additionally grounded twist free and hardened by a special process to prevent stainless features.

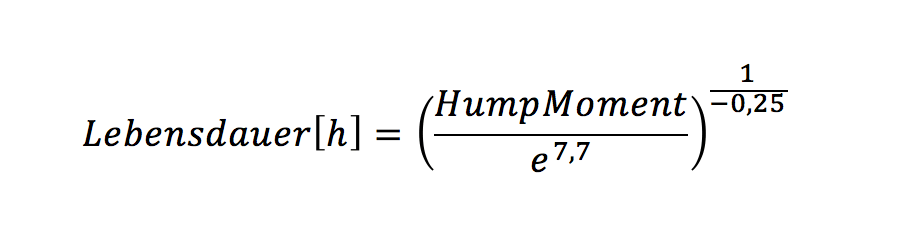

Service life

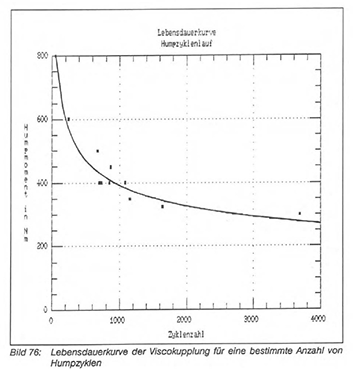

Steyr-Daimler-Puch had the durability of the T3 Syncro viscous coupling tested in a diploma thesis under specified operating conditions. The investigations showed that the service life of a viscous coupling depends on the differential speed, the power loss and the height of the Hump-torque. On principle we have to distinguish between two separate service life- categories though:

VISCOUS CONTINOUS RUN

The service life of a viscous coupling in Viscose-mode (fluid friction) depends mostly on the wear resistance of the silicone oil, since the aging of the silicone oil leads to a slow hardening of the viscous coupling. Therefore the increase in viscosity of the oil due to the oxidation of the oxygen causes a rise in transmitted torque over time.However, this undesired behavior can only be observed with viscous couplings whose gas bubble consists of conventional ambient air.

All our viscous couplings are filled with an inert gas. This will prevent the silicone oil from gradually thickening due to oxidation.

HUMP CYCLE STABILITY

During Hump-mode the plates experience wear-intensive mechanical and thermal stress. From a certain abrasion onwards, the plates lose their ability to initiate Hump. The Hump-moment which is important for self- protection cannot be achieved anymore. This can lead to an overheating of the coupling, causing the inner pressure to rise unstoppably.In the case of T3’s viscous coupling, the steel cover bulges before the X-rings fail and the VC starts to leak silicone fluid. At the T4 Syncro, the steel cover bulges also at first, but after that the aluminum housing usually ruptures. In both cases, at least the defective plates must be replaced.

FURTHER INFORMATION CONCERNING SERVICE LIFE

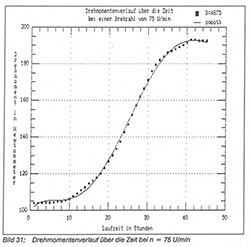

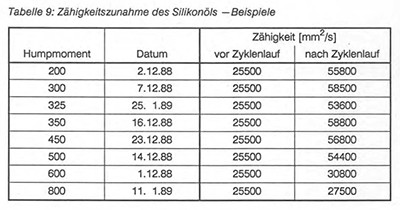

VISCOUS CONTINOUS RUN - INCREASE IN VISCOSITY

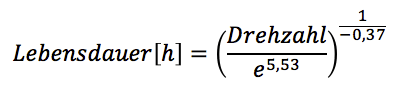

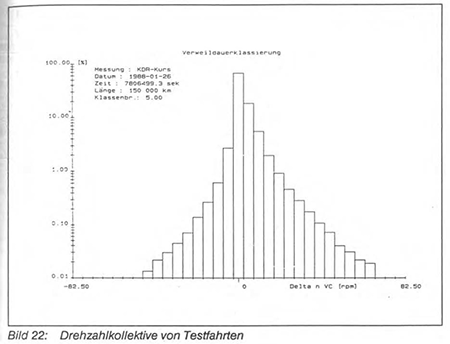

VISCOUS CONTINOUS RUN – SERVICE LIFE FUNCTION

Hump - Service life